Projects

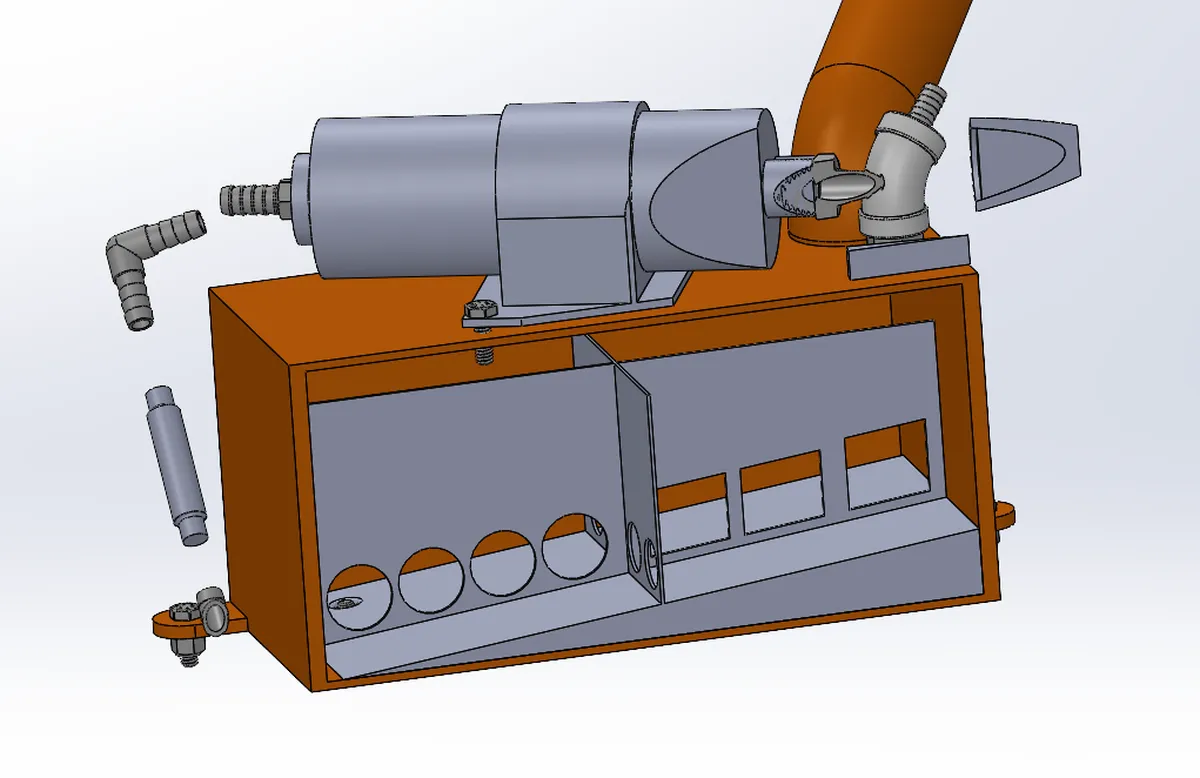

FED101 Final Project: Exoskeleton Elbow Mobility Assistive Device

First-Year Engineering Design Showcase – 1st Place

Project Overview

This project focuses on designing an exoskeleton-style assistive device powered by a precision-controlled servo motor system. The mechanism supports arm movement by providing guided actuation and controlled force assistance. A key added feature is a sliding joint that increases the device’s degree of freedom, enabling smoother and more natural motion when the arm contracts. This design enhances mobility, responsiveness, and ergonomic support for the user.

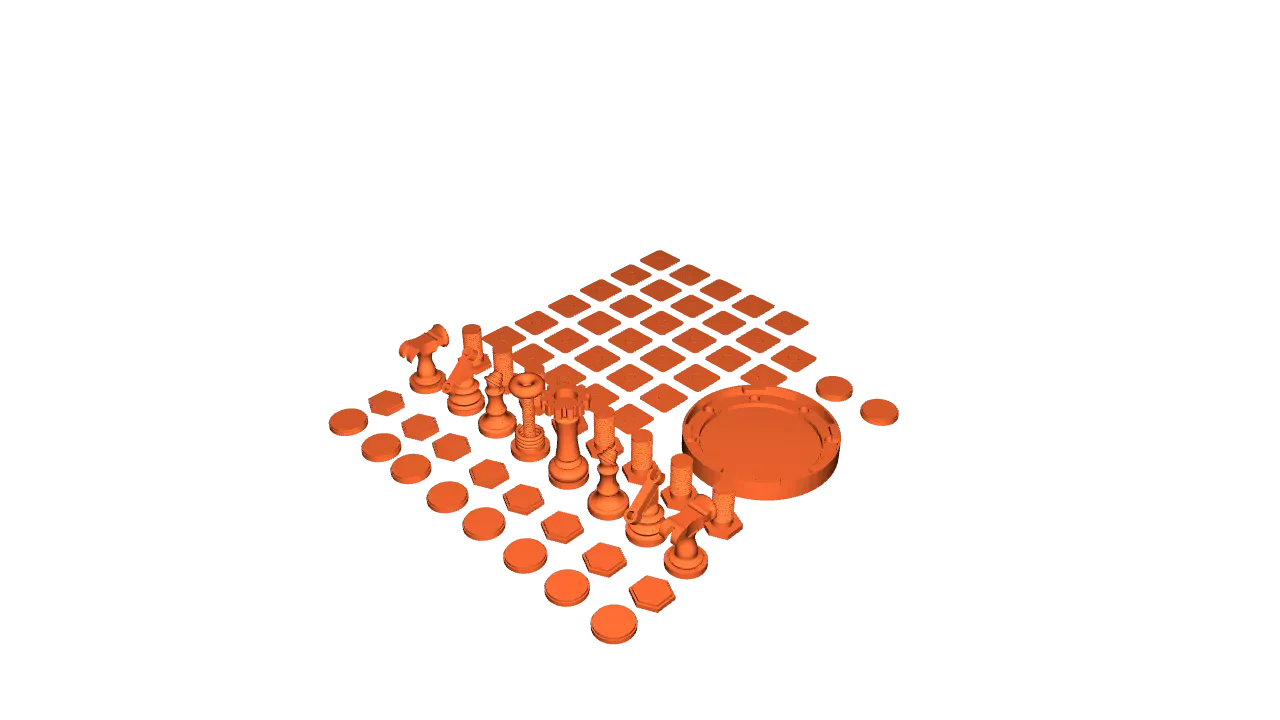

Engineering-Themed Chess Set

3D-Printed Custom Chess Set Inspired by Engineering Tools

Project Overview

Designed an engineering themed chess set with pieces modeled after workshop tools and equipment. The queen is a Tesla coil, the king a gear, pawns are hex bolts, rooks are hammers, bishops are TIG welders, and knights are wrenches. The print in place board rolls up and stores all pieces with end caps for easy transport. The set is magnetic, customizable, and easy to print.

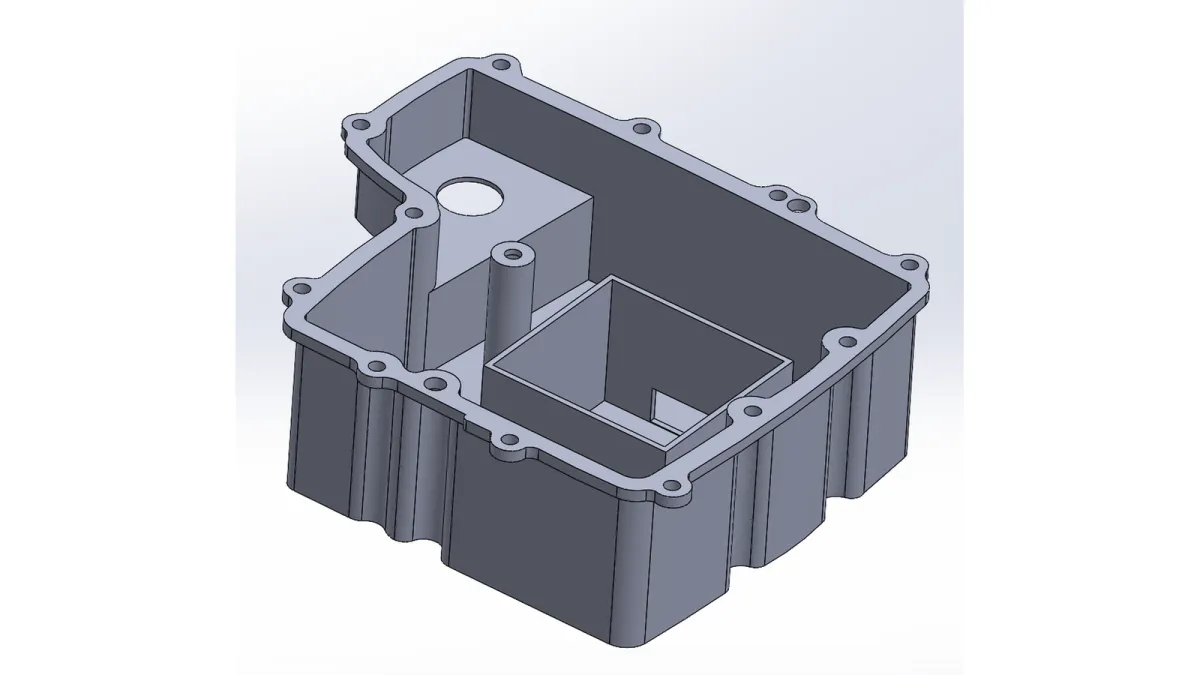

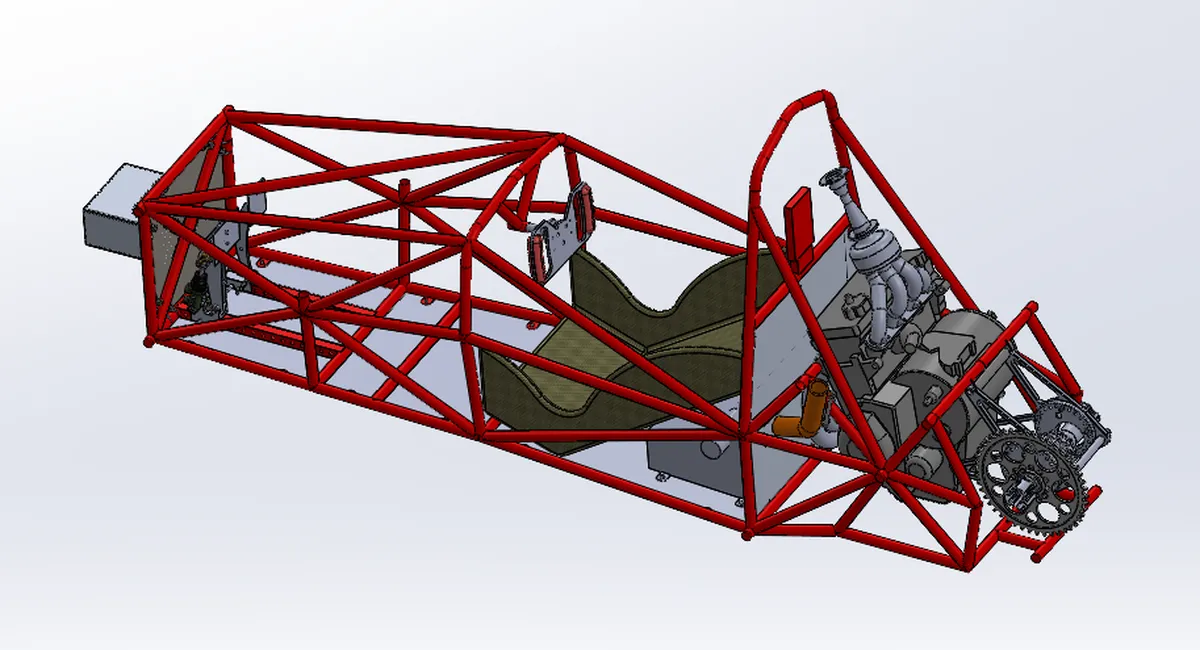

Formula SAE Powertrain: Fuel Tank & Oil System Development

Fuel Tank & Lubrication System Engineering for the 2010 Yamaha R6 (FSAE)

Project Overview

Contributed to the early Formula SAE powertrain team by designing a fuel tank around the 2010 Yamaha R6 engine requirements. Focused on fuel flow, pump fitment, and overall packaging while gaining design experience. The fuel tank included internal baffles and fuel foam to control slosh and maintain consistent fuel pickup during cornering. Assisted with component sourcing and collaborated on an improved oil pan concept featuring a trap door system for reliable oil delivery under lateral loads.

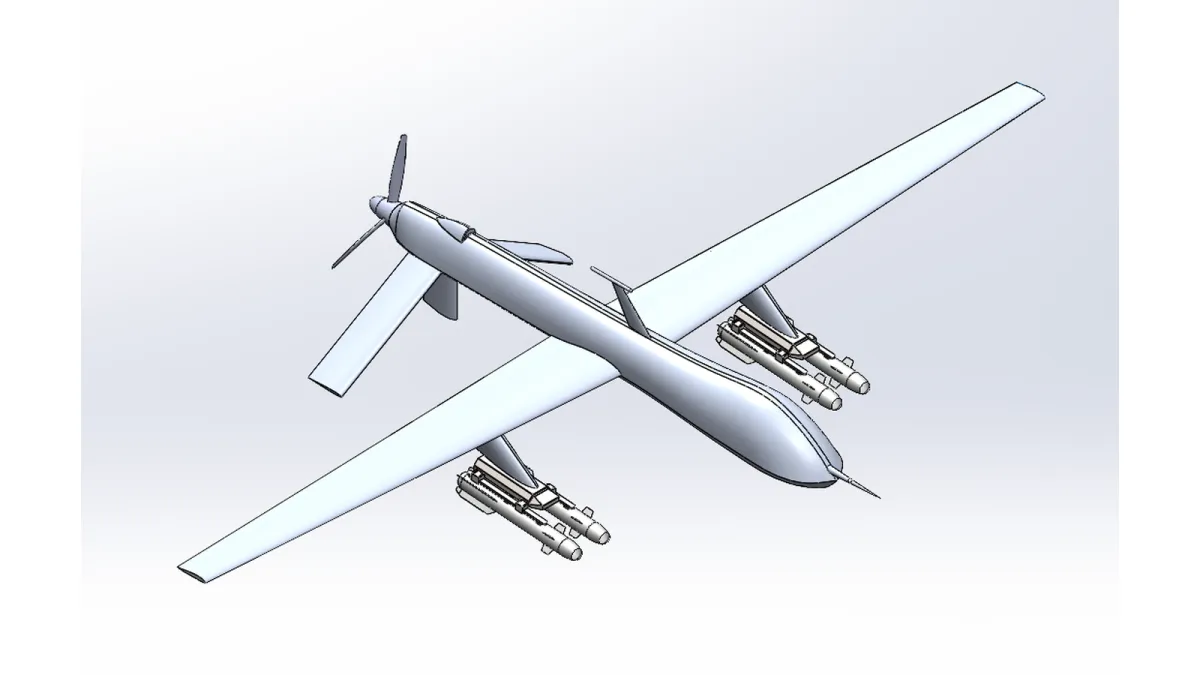

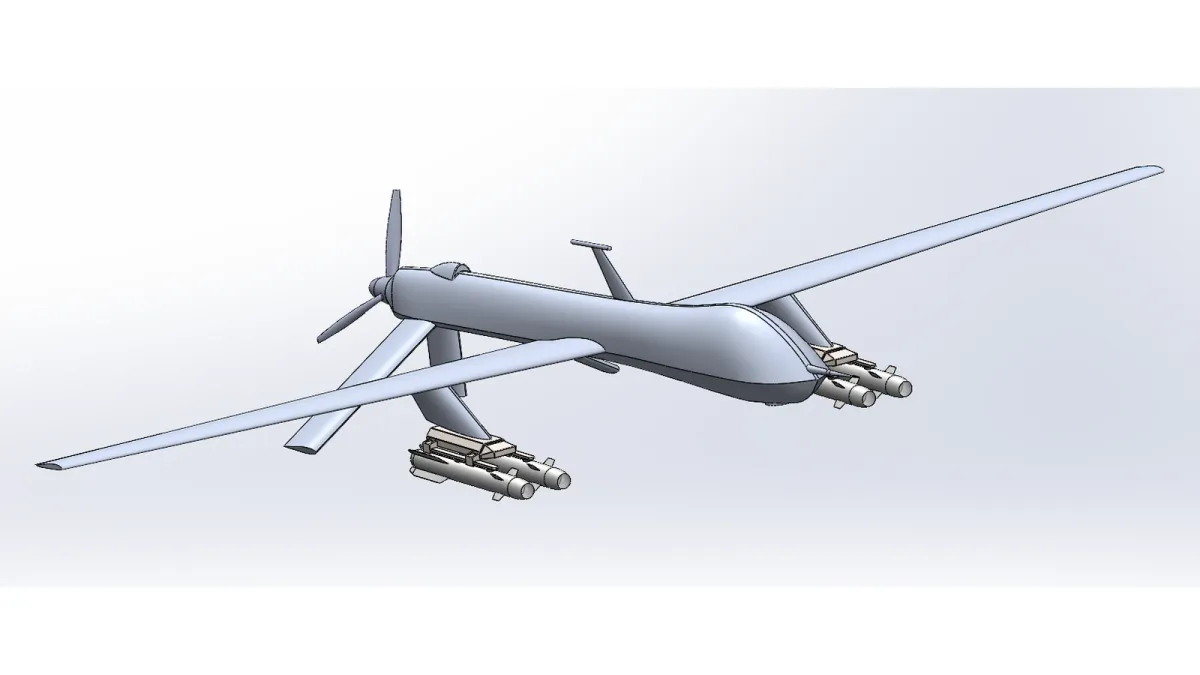

Predator-Style UAV CAD Model

Detailed Aircraft Assembly

Project Overview

I collaborated with a small team to design a Predator drone UAV in SolidWorks. Using UIUC airfoil data, we developed accurate wing profiles that improved performance and refined the overall geometry. This project furthered my understanding of aircraft design.